In the beginning there is only dirt. That’s where we start. A good geotechnical report that has all the information we need to do it right. After a thorough geotechnical review, we start the design process where we tear each unit apart and transform the architect’s vision into a real buildable set of drawings, using framed wall dimensions.

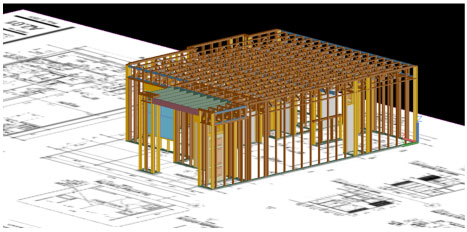

By framing the units first, as a framer, we see the need for small dimensional changes such as moving walls for tub clearances and door and casing interferences. At the unit stage we analyze and select floor framing material based on spans, loads and mechanical requirements.

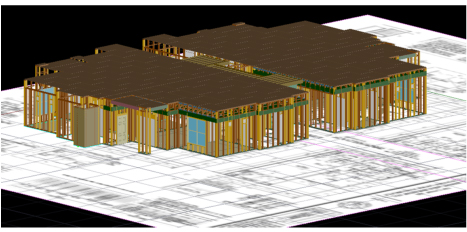

After the unit designs have been checked and re-checked, we assemble the buildings into framed levels. Then we frame the roof in the roof truss design program, this allows us to accurately see the loads and end reactions being generated by several roof truss design concepts.

Unit plans are framed with real wall framing dimensions and as-built techniques. Real window and door rough openingsare used and critical path dimensions for tubs, door openings, cabinets and trim are checked and verified.

Units are assembled into building levels, where issues such as air spaces, corridor framing, stairs and landings can be analyzed.

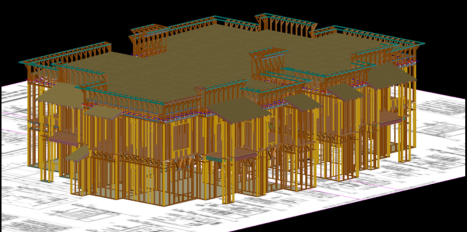

Foundations are imported into the model, upper levels are framed and roof trusses and sheathing are applied. Mechanical models can be imported for clash detection and coordination. At this point the model can be exported to a bill of materials (BOM) report.